MIL-DTL-1716J

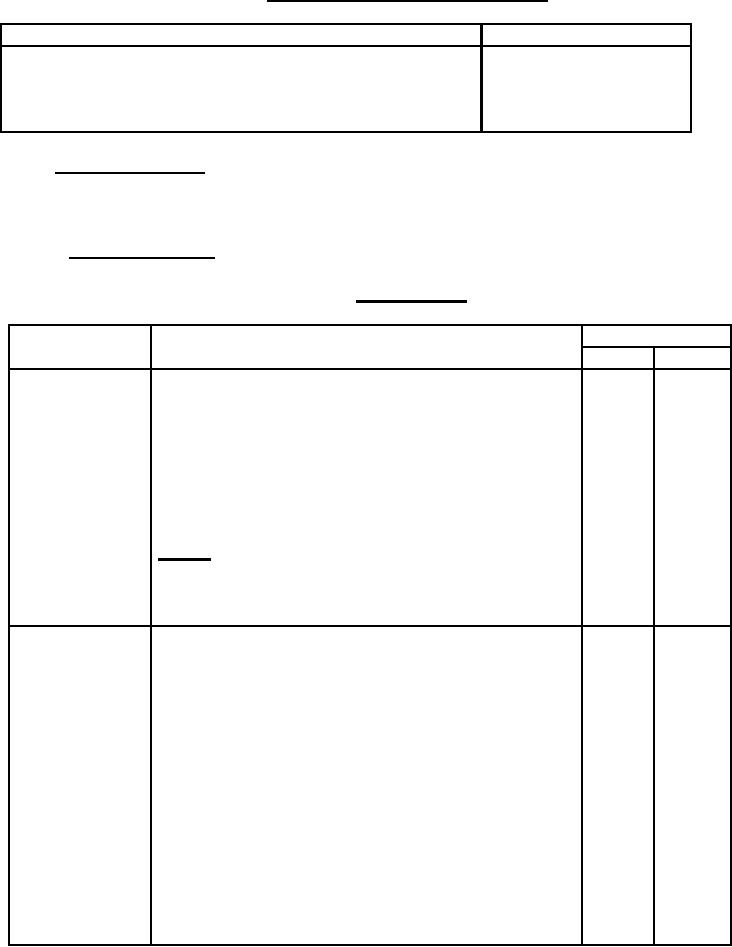

TABLE II. In-process examination of finishing

Requirement or operation

Requirement

Zinc plating

3.4.1

Pretreatment of magnesium surfaces prior to assembly

3.4.2

3.4.3

Priming of tubular sections, plug, and spindle prior to

assembly

4.3.3 End item inspection. The end item shall be examined in accordance with 4.3.3.1 and

4.3.3.2. The lot size shall be expressed in units of one pole. The sample unit shall be one

completely fabricated pole.

4.3.3.1 Visual examination. The end item shall be examined for the defects listed in table III.

TABLE III. Visual defects

Classification

Examine

Defect

Major Minor

101

Finish

Not finish as specified, e.g., locks not zinc plated

Aluminum and magnesium components not enameled

102

as specified

201

Color of finish is not as specified

202

Coating not smooth or uniform

203

Finish is not dry, i.e., wet or tacky to touch

204

Runs, wrinkles, streaks, grit or coarse particles

NOTE: Defects in finish attributable to extension

during examination will not be scored as a defect.

However, the contractor shall touch up areas of finish

damaged during examination

103

Any part not fabricated of the specified materials

Construction

104

Any component, e.g., the lock, not fabricated as

and

specified

workmanship

105

Component missing, e.g., tubular section, lock or

spring pin

205

Component is split, punctured, malformed, deformed,

206

or fractured

207

Spring pin is loose or is not flush with tubular section

Fluting on spindle or plug is missing

208

Plug end of bottom tubular section not swaged against

plug

209

Spindle end of top tubular section not swaged against

210

spindle

211

Plug vent hole missing

Slot missing in tubular section

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business